Introduction:

Motor bearing seal belongs to dynamic seal to prevent oil leakage, BHS company R&D improved "polyimide floating seal ring" for solving oil leakage due to traditional floating seal production process, material, and structural problems can not long time work in high temperature, high speed and high vacuum and radiation environment.

Polyimide labyrinth type floating sealing ring for motor adopts aerospace industry thermoplastic engineering polyimide material PI-YS20,this material has the excellent properties of high insulation, wear resistance, self lubrication, high temperature resistant, stable size, do not wear shaft ,which application to slide bearings of large and medium-sized motors.

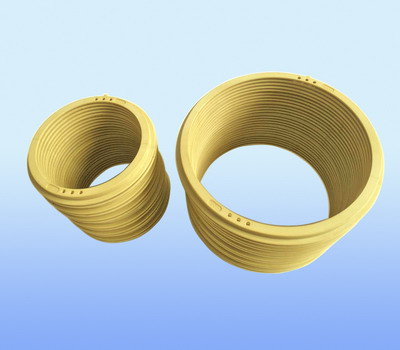

Polyimide labyrinth type floating seal ring structure and usage:

1.Polyimide labyrinth type floating seal ring is dual-ring structure, consist of oil return hole, positioning pin and a spring groove;

2.Labyrinth floating sealing ring has four pieces of inside slot ,one piece of outside slot that used for circlip.

3. the positioning pin position has three round holes, its opposite position also has three round holes,all holes used for oil return slot.

Products applicable to variety of generator unit, desulfurization, denitration equipment, all kinds of power station auxiliary equipment and DC and AC motors. This seal has been widely using for coal mines, metallurgy, petrochemical, power generation and other industries .This seal has became designated product by Shanghai motor company, Nanyang explosion proof motor company, Jiamusi Electric company, Zhejiang Shenke, etc.large motor, bearing manufacturers.